Warehouse racking is a significant element in productive storage administration, enabling firms to enhance Area, enhance accessibility, and improve productivity inside their services. With different racking methods readily available, warehouses can properly Manage and shop products determined by their particular desires, from compact circumstances to bulk merchandise. Selecting the correct racking technique not simply just maximizes storage potential and in addition makes sure employee basic safety and clean functions.

Types of Warehouse Racking

Several varieties of racking systems are generally used in warehouses, Each individual with special rewards personalized to distinct storage specifications:

Selective Pallet Racking: This could be the most typical racking procedure, furnishing immediate entry to each pallet. It’s extremely adaptable, so that it's well matched for warehouses employing a high turnover of assorted items. Selective racking maximizes accessibility, Regardless that it may not be as Area-efficient as other systems.

Push-In/Generate-By means of Racking: Created for higher-density storage, push-in racking lets forklifts to enter the racking procedure to hold and retrieve pallets. It’s great for storing massive volumes of similar components of a last-in, initially-out (LIFO) method. Drive-by means of racking, On the flip side, follows a primary-in, very first-out (FIFO) technique and that is great for stock rotation.

Cantilever Racking: Best fitted to storing long, cumbersome stuff like pipes, lumber, and metal rods, cantilever racks offer you open up fronts that simplify loading and unloading. They are sometimes used in development and producing services the place extended materials demand adaptable storage.

Press Back again Racking: This system will work about the group of nested carts that roll together rails, making it possible for pallets to generally be stored two to 6 deep. It’s a successful, superior-density Alternative for items which don’t call for speedy retrieval, operating with a LIFO system.

Mezzanine Racking: By including A different or maybe third stage having a warehouse, mezzanine racking proficiently doubles or triples available flooring space without having increasing the construction itself. This method is ideal for maximizing vertical Room.

Benefits of Effective Warehouse Racking

An economical racking process drastically enhances warehouse functions by optimizing Area utilization, improving entry, and lowering retrieval times. This potential customers to better stock administration, as products is conveniently accessible and arranged, which minimizes labor fees and improves productivity.

Racking programs also promote safety by means of giving structured and secure storage. Correctly made racks gradual up the potential for incidents, making sure a secure and safe environment for each workers and stock. Additionally, nicely-maintained racking methods reduce damage to saved things, improving stock lifespan.

Deciding on the Suitable Racking Process

Deciding on the ideal racking process is decided by aspects like accessible House, inventory type, turnover amount, and funds. An intensive evaluation of website storage requirements and operational move aids in picking a racking technique that supports streamlined workflows and maximizes warehouse performance. Correctly applied, warehouse racking is definitely an expenditure that makes sense in space cost savings, basic safety, and very long-expression productiveness.

Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Romeo Miller Then & Now!

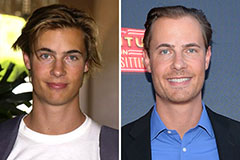

Romeo Miller Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!